Date: July 2019

Client: Major Operator

Location: Central North Sea

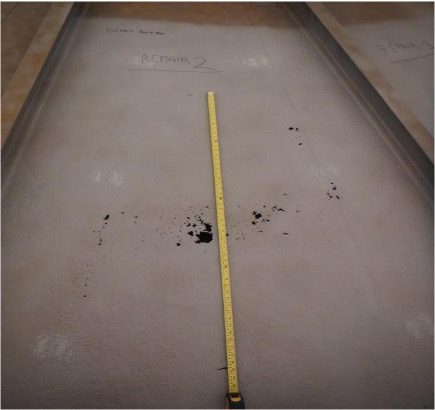

Scope

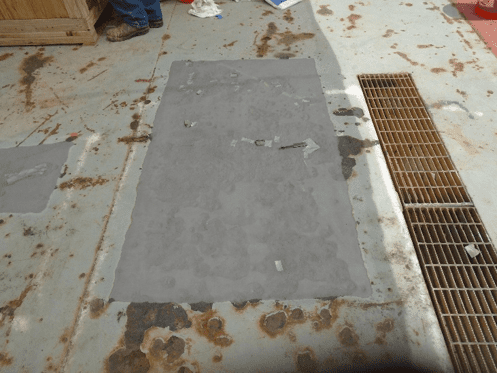

The pipe deck on the client’s asset had suffered extensive corrosion resulting in severe wall loss and through wall defects. This was the third phase of a 22 bay pipe deck repair. 7 bays measuring 3m x 6m required a repair solution totalling 126m2. Multiple through-wall defects and low wall readings were found.

Solution

The bays were grit blasted to a SA2.5 surface profile. For any areas that were through-wall, 6 layers of our DRS Carbon Fibre solution was utilised. This consisted of a 2 layer composite plate – fully cured – bonded directly over the defects followed by a 4 layer wet lay up. For all non through-wall areas, 4 layers were applied. Fully engineered calculations produced by the ICR technical team.

Results & Benefits

- The repairs were designed to seal all through wall defects as well as providing an engineered design lifetime of 20 years

- The DRS resins provide a rubberised molecule resin which absorbs and dissipates impacts from thoroughfare and use as a landing area

- An anti-slip coating was also applied over the completed pipe deck area. Long term corrosion protection

- No hot work required

- No heavy lifting or steel components

| Date | Client | Location |

|---|---|---|

| 2019 | Global Supermajor Operator | Gulf of Mexico |

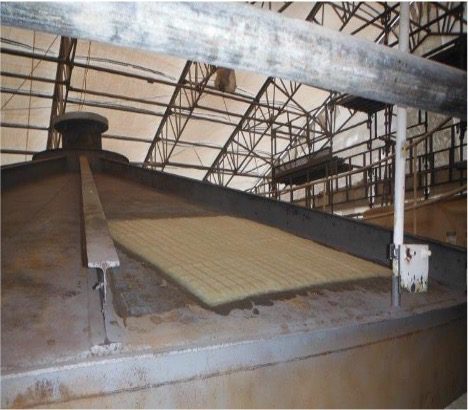

Scope

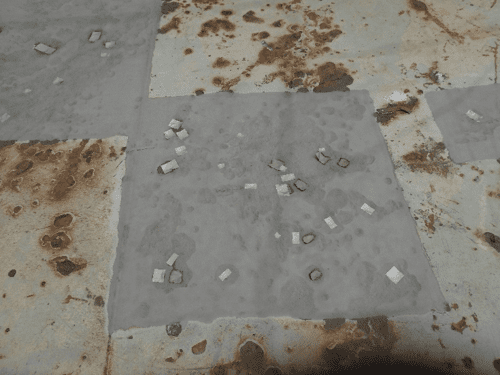

It was advised that a logging support deck plate onboard a supermajors platform was suffering from external corrosion and various through-wall defects. Four areas of the logging plate deck required composite repairs.

Solution

Following an engineering assessment, ICR proposed four layers of Technowrap™ Structural carbon fibre combined with our DRS resin system to be applied over the defect areas. The design challenge for the repair was to ensure enough strength within the repair to withstand the applied load, but also impact tolerance from dropped objects. A design methodology using rubber toughened epoxy has been developed by ICR ensuring both strength and stiffness as well as impact tolerance.

Results & Benefits

- The application of the Technowrap™ DRS went as planned and without delays

- The integrity of the deck was restored for a 20-year defined lifetime

| Date | Client | Location |

|---|---|---|

| March 2022 | Energy Company | Nuclear Power Station, England |

Scope

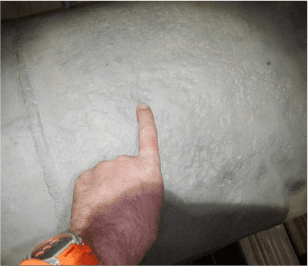

ICR’s UK Onshore team was asked to complete a Technowrap™ composite repair scope at a nuclear power station site in England where replacement was not practicable due to severe access restrictions and isolation issues.

Solution

Although typical composite resin systems within a confined space area require breathing apparatus, ICR was able to use its bespoke resin system and installed a Technowrap™ engineered composite repair to eliminate the requirement. Following visual inspection and risk assessment, the area was grit blasted with the pipework remaining in service at all stages. The repair was implemented and signed off within a 3-day window.

Results & Benefits

- No hot work required, reducing safety risk

- Cost effective solution

- 20 year design life achieved

- Has led to several further scope enquiries from client

Client Feedback

“We would also like to pass on our thanks to your Team for the work carried out. It was a job well done with no issues and to an excellent standard.”

| Date | Client | Location |

|---|---|---|

| July 2021 | UK Medical Products Supply Company | South East England |

Scope

On removal of insulation during plant shutdown, severe external corrosion under insulation was found on an approx. 3m length of 2” to 4” diameter water/ethanol pipework between valves and branches. ICR were approached to propose a solution to restore the integrity of the pipework and allow the plant to be rapidly returned to service. The repair design conditions being 2.5barg pressure, ambient/-35°C temperature with 2 year design life.

Solution

A Technowrap™ 2K LT engineered composite repair solution was proposed with surface preparation by hand to minimise chance of pipework going through wall. ICR mobilised technicians and material to site. During the repair, additional pipe sections were found to be corroded and repair scope doubled. ICR provided additional materials and technicians with night shift established to enable repairs to be completed to the required schedule. From initial approach to the repairs (including additional scope) being completed and signed off, was just over a week.

Results & Benefits

- Pipework integrity restored

- No through wall penetration during repair

- ICR technicians worked day and night to complete the repair with increased scope allowing the plant to return to service in line with schedule

| Client | Location |

|---|---|

| EDF | Heysham 1 Power Station |

Scope

EDF Carbon Steel 20” Condensate Pipework Repair Water Line (TG2- 20” Condensate Return). The line was suffering from a through wall defect caused by external corrosion.

Solution

ICR were requested to provide an engineered repair solution to restore the integrity of the line for a design life of 5 years. This repair is subsequently designed for a through-wall defect.

Results & Benefits

- Engineering design calculation complete with design sketch, materials and manpower to complete the 15-layer repair using the Technowrap™ 2K cloth with the Technowrap™ LT resin.

- No hot work required

- Defined life repair of 5 years

| Date | Client |

|---|---|

| April 2022 | EDF Energy |

Scope

EDF Emergent requested out of hours on Bank Holiday Monday 18” Carbon Steel Gen TX 2 Spare Oil Conservator which was suffering from a through-wall defect due to external corrosion of the weld. This repair was subsequently designed for a through-wall defect.

Solution

ICR were onsite the following day, with an engineered repair solution of 8 layers of Technowrap™ 2K LT was delivered to restore the integrity for a design life of 15-years.

Results & Benefits

- Technicians onsite within 24 hours, installation was delivered, QA/QC checked and handed back to site in a 3 day window

- 15 year Design life

| Date | Client | Location |

|---|---|---|

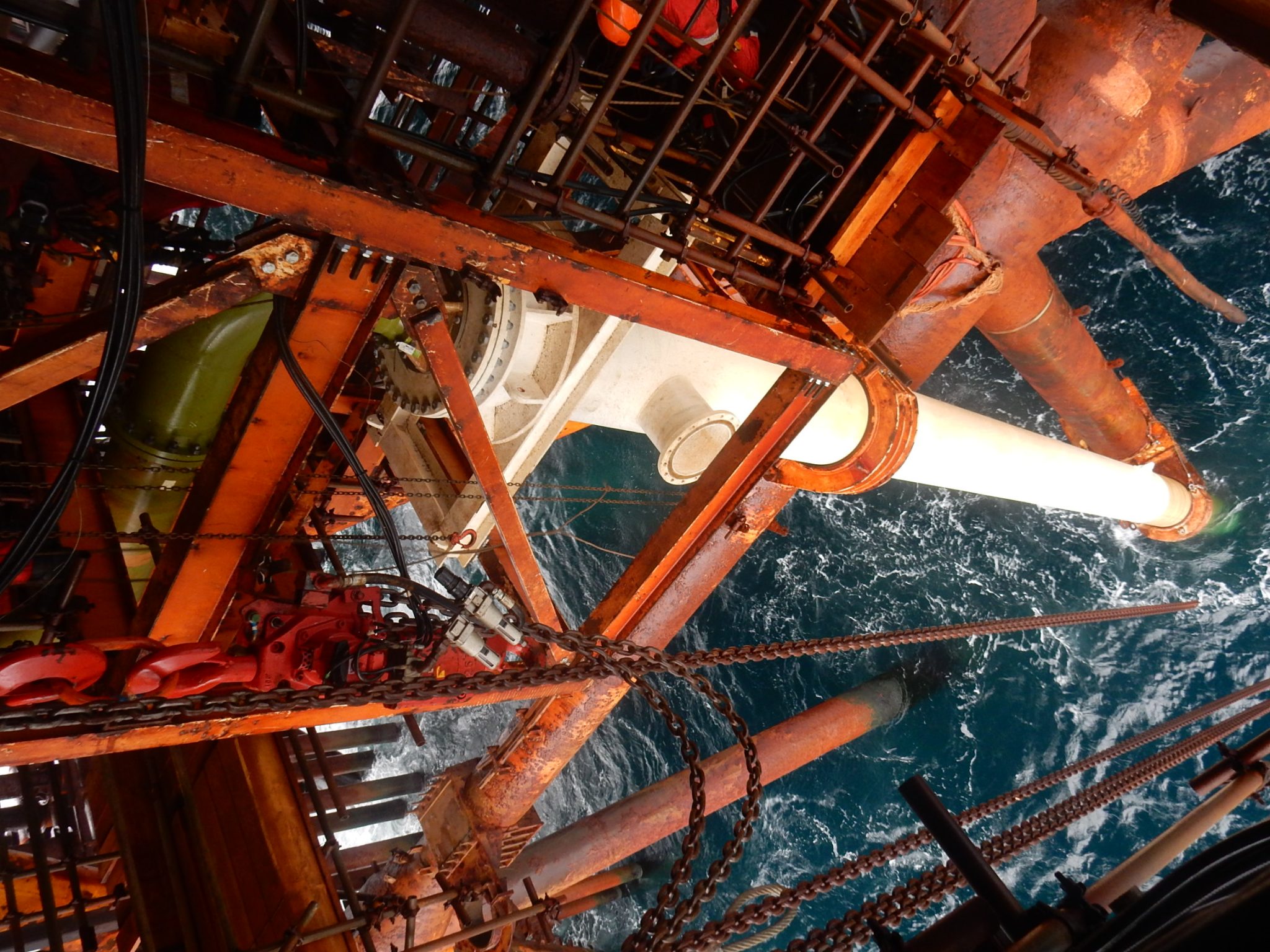

| August 2019 | Major North Sea Operator | Onshore Aberdeen |

Scope

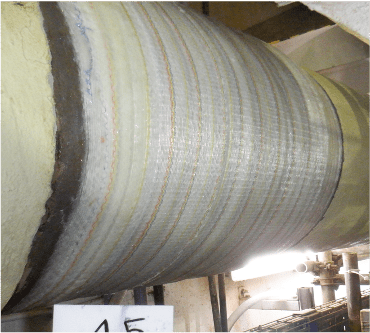

ICR were engaged to provide a engineered composite repair solution on a produced water caisson prior to installation offshore. The previous caisson was corroded due to wave action causing thermal cycling.

Solution

Two new sections of a 12” caisson were fabricated and sprayed with an internal coating prior to ICR applying the composite solution. It was a design requirement that surface preparation to Sa2.5 and was achieved prior to the application of 4 layers of Technowrap™ 2K using HT (High Teemperature) resin.

These were then welded together and an angular profile of 45μ was achieved using bristle blasters. A composite wrap was then applied to cover the welded section. Heat blankets were used througout the process to assist curing.

| Design Temperature | 100°C |

| Design Pressure | 2.5bar |

| Material Grade | Super Duplex |

| Surface Preparation | Sa2.5 |

The change in temperature was taken into consideration by derating the allowable strains in line with ISO 24817.

Results & Benefits

- ICR technicians worked day and night for a total of 7 days to complete the repair

- A repair lifetime of 20 years was given

- The solution will prevent future corrosion due to thermal cycling, maintaining the integrity of the structure

| Date | Client | Location |

|---|---|---|

| April 2022 | EDF | North West England |

Scope

Various repairs carried out on a Carbon Steel Demin Water Reserve Feed Tank. The tank was suffering from through-wall defects due to external corrosion.

Solution

ICR were requested to provide an engineered repair solution to restore the integrity of the tank for a design life of 20 years.

Results & Benefits

- ICR provided engineering design calculation complete with design sketch, materials and manpower to complete the 8-layer repair using Technowrap™ 2K HA

- 5 x Dayshifts, 5 x repairs

- Fast & cost effective versus replacement

| Client | Location |

|---|---|

| Major Middle East Operator | Oman |

Scope

An isolation joint (as part of the cathodic protection system) of a 36” pipeline was leaking through the internal sealing mechanism of the joint. It was not possible to isolate this joint so the repair had to be applied live. Therefore, one of the critical aspects of this repair application was the associated safety aspects of diverting the leaking gas from the joint while the repair was being applied.

Solution

The installation procedure for the clamp and composite repair consisted of the following steps;

1. Clean surface of joint and seal leak

2. Apply temporary clamp and gas diversion system

3. Prepare surface of pipeline

4. Apply composite repair

5. Perform QA/QC checks

The proposed solution involved first applying a temporary clamp over the leaking part of the joint and then applying a composite repair over the clamp to ensure longevity of the repair solution. ICR project managed the complete activity of this repair including surface preparation, clamp design and installation and composite repair design and installation.

The repair design was performed according to ISO/TS 24817. Due to live nature of the repair, the repair design was split into two parts. The first part involved the design of a temporary clamp and gas diversion system. The second part was the design of the composite repair to ensure the leak sealing capability of the repair. The solution was 15 layers of Technowrap™ 2K in the form of a fully circumferential wrap over the temporary clamp and extending along the axial length of the pipeline beyond the clamp by 300 mm.

Results & Benefits

- The application of the Technowrap™ 2K HA went as planned and without delays

- The repair was designed with a lifetime of 5 years.

- Repair was applied whilst line was live, meaning no shut down for client

| Client | Location |

|---|---|

| Major African Operator | Nigeria |

Scope

A 48” Main Oil Export line in Africa had sustained patches of external corrosion over a number of areas on the line. The client required an engineered composite repair to reinstate the integrity of the line.

The scope of work was to provide an engineered design, with 20 year repair lifetime, personnel & Technowrap ™ 2K HA materials to affect repair. Design pressure of the line was 19.6 bar g, with design temperature of 49ºC

Solution

The engineered design for the Technowrap™ 2K HA repair was performed according to ISO 24817.

Surface preparation to Sa2.5 was carried out by the client to ensure best bond of repair to substrate. The Technowrap™ repair was then installed according to ICR Installation Guidelines.

Existing concrete pipe supports were destructed and new concrete pipe supports cast and constructed to accommodate repair sites.

The client was also required to excavate trenches to allow the Technowrap™ personnel full access to the pipeline & allow the repair to be applied around the full circumference of the pipeline.

Results & Benefits

- Integrity of line was reinstated by repair

- 20 year design life